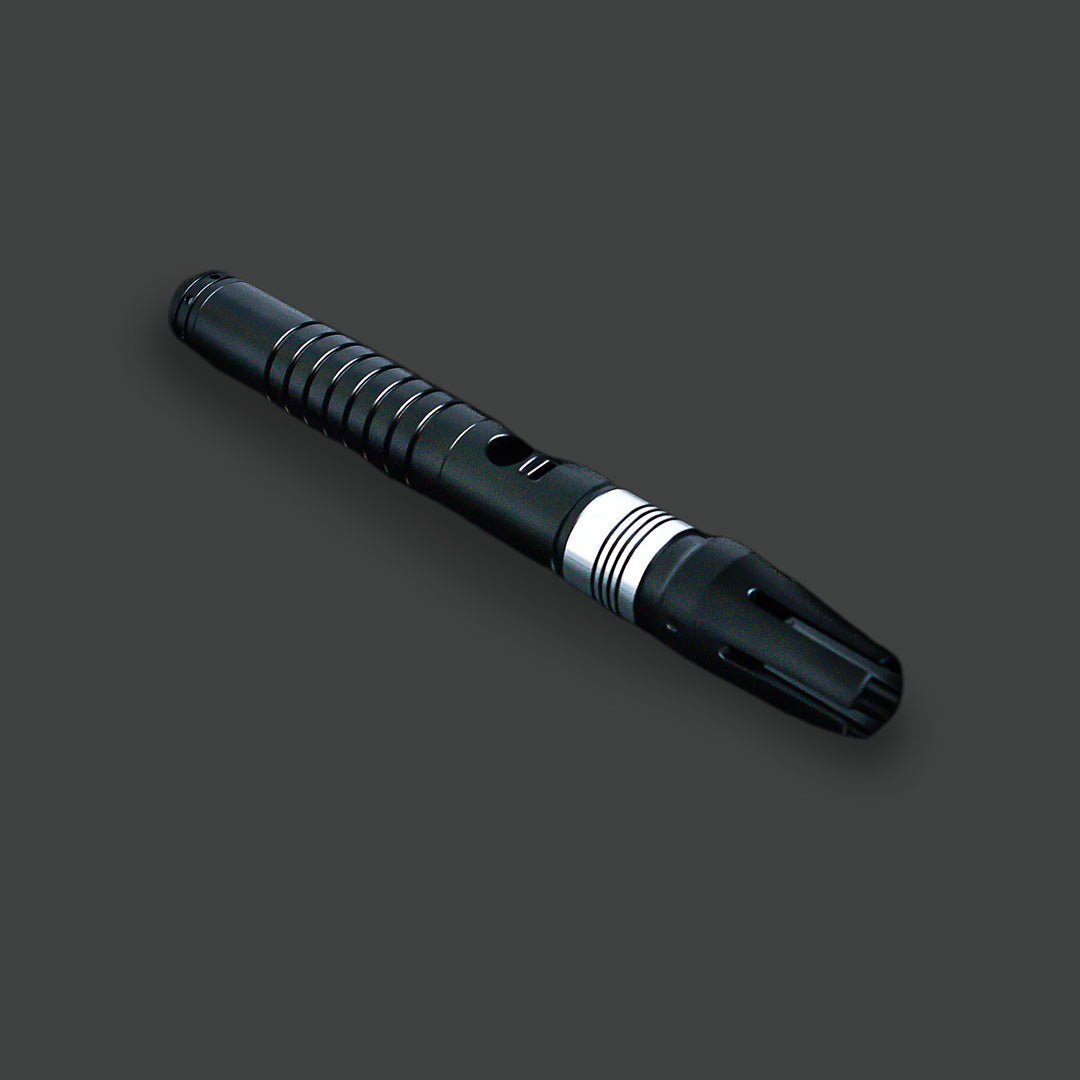

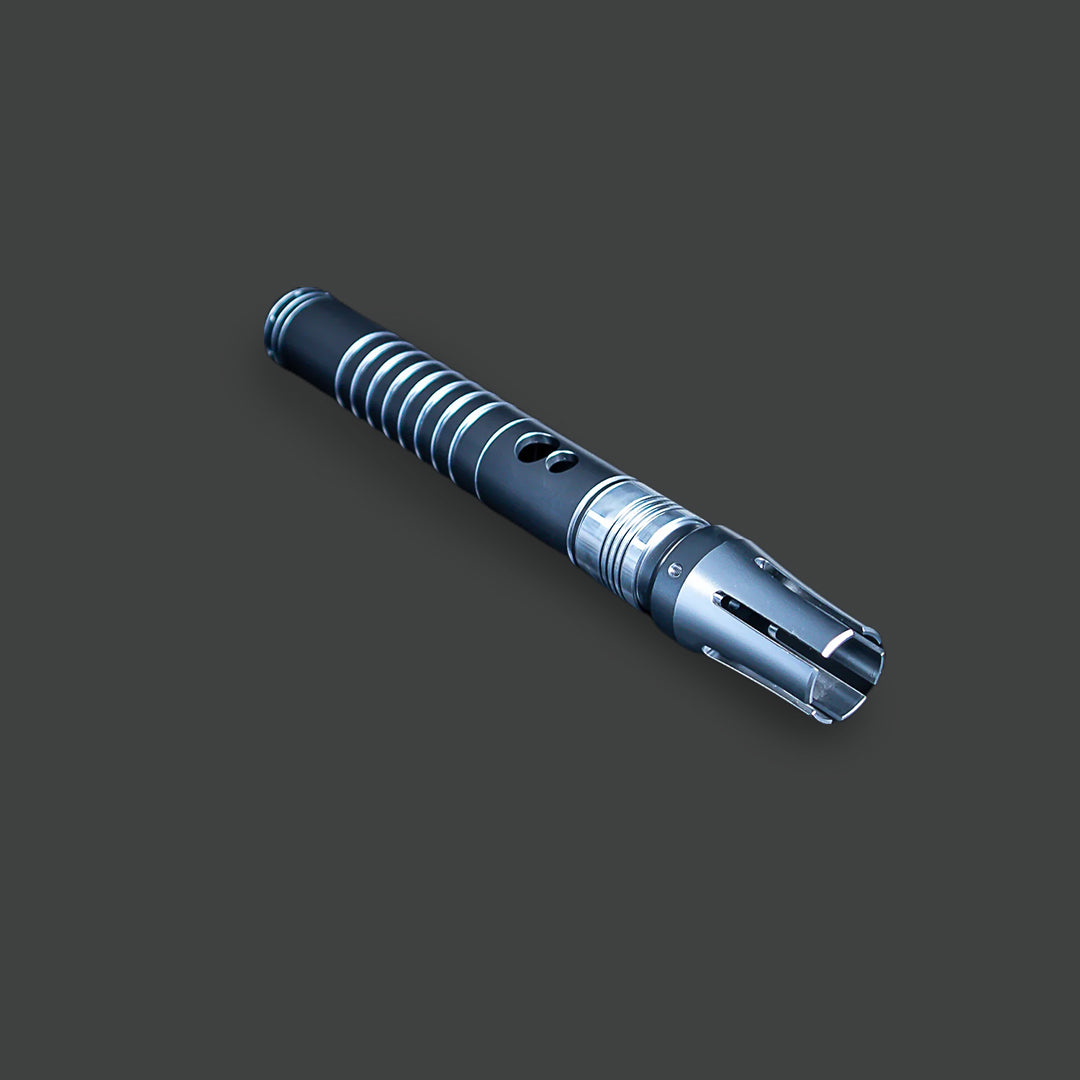

Radiance (Empty Hilt)

Radiance (Empty Hilt)

🎁 30% off : (Use Coupon : OFF30)

Couldn't load pickup availability

A robust and long-lasting alloy of aluminum was used to create the hilt. The hilt also contains numerous components that can be dismantled, allowing the sabers to be customized with different parts.

Please keep in mind that this is for an empty hilt (no electronics or blade are included).

Weathering, Etching and Battle Scarring

We have the option for your sabers to be weathered, etched or battle scarred.

For the weathering, this means that we take your hilt and make it look like it has had long exposure to the atmosphere, giving it a worn, run down look and a battle used kind of look.

With etching we add a stencil in the design you choose to protect your hilt and then use acid to remove the remaining metal giving a 3D textured pattern on your saber.

Battle scarring requires us to make cuts and gouges to your hilt to make it look like it has been used in combat and been hit by another saber.

Each process requires us to either sand parts of the hilt, add marks, scratches, dents or other battle like scars or by adding paints or chemicals to adjust the look of feel of the hilt.

This is very labour intensive and can extend the lead time and increase the cost of the saber. It can take up to 2 weeks to get your saber customised - this is on top of the normal 2 week production time for the parts, core and assembly of everything.